Pantone Matching On USB Flash Drives – Not an Exact Science

If you want to make an impact with your printed promotional USB flash drives then one option available to you is to colour match, or pantone match as its commonly referred to, the body shell of the USB flash drive.

Most USB flash drives are manufactured in a range of standard colours with some of the more popular models like the Twister USB flash drive typically available in around 20 different colours. Obviously, the more standard colours there are available for a given model, the more likely it is that you are going to find a colour that works with, and compliments your company or school logo.

But, if you want a specific colour for your USB flash drive then the only option is to find a supplier not only willing to produce the flash drive in your preferred colour but to find one that is able to do it at a reasonable price. Pantone matching or colour matching the plastic that forms the shell of your chosen flash drive is a manual process, its adds time to the manufacturing schedule and it is not an exact science. These are all elements that build in cost and often the cost of pantone matching can be high, particularly if you only order a small number of USB flash drives – this is simply because some of the fixed costs involved in creating the specific colour of plastic to be used in the manufacture of your flash drive are amortised over a small number of USB sticks.

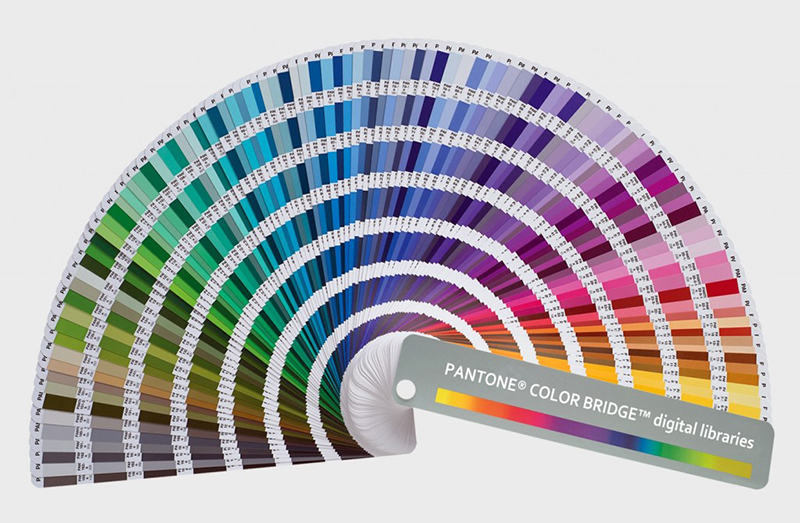

The basic principle of pantone matching is that each final “mixed” colour is given a number (a pantone number) thus ensuring that this colour can be repeated over and over again by a printer to ensure consistency of print/colour. Pantone matching is the way in which companies manage consistency of brand and their brand logo. For example, every time you see the Coca Cola red it is the same red irrespective of where you are in the word, it’s the same with the Ford Motor Car Company blue or the Starbucks Coffee green. Consistency of colour and of brand representation is incredibly important to build consumer awareness, association and confidence.

However, a word of warning, even when you use pantone matching there is always going to be the possibility of minor colour variations because paint and dyes react different depending on the material they are applied to or mixed in with. When pantone matching the plastic body shell of a USB flash drive there are three main issues to consider:

- The colour matched plastic used to form the shell of the flash drive body is mixed by hand so the end result is largely down to the experience of the individual undertaking the mixing. Typical results are excellent but because it’s largely a manual process there is room for interpretation to creep into what many expect to be an exact science.

- Repeat orders of the same pantone matched USB flash drives may not be exactly the same. Because the process to create a pantone matched flash drive relies on a human to mix the colours with the core plastic material and it’ s therefore possible for there to be minor colour variations between each batch produced – this is no different from than when you buy rolls of wallpaper or some specialised paints - batches will vary so be prepared for this. If you cannot accept any colour variations no matter how small from one batch to the next then consider buying blank “shells” from which future orders can be made.

- Pantone matched inks and dyes look different depending on the underlying material and colour they are applied to. So, if you are using a pantone matched ink and applying it to a white plastic it will look different compared to when the same ink or dye is applied to a silver metal clip (like the type used to form the out piece of the popular Twister USB flash drive)

Pantone matching promotional USB flash drives can create fantastic results and you’ll end up with a flash drive that is unique to your company but do be aware of the above “health warnings”. Although pantone colour coding was introduced to help reduce and ideally eradicate colour variations the reality is that minor colour variations will always occur when you are manufacturing a product that involves some degree of “manual” work and where the finished colour is applied to anything other than white paper.